Buy from World's Top Leaders in Scrap Recycling Industry With SGS Pre & Post Inspection Reports.

Buy from World's Top Leaders in Scrap Recycling Industry With SGS Pre & Post Inspection Reports.

Buy from World's Top Leaders in Scrap Recycling Industry With SGS Pre & Post Inspection Reports.

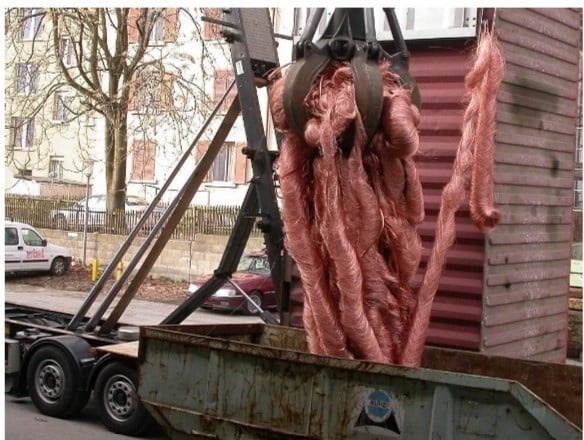

The process of producing Copper Millberry Scrap is one of the world’s most effective recycling endeavours.

1 DOLLAR IMPORTS, LLC works with some of the world’s leading Copper & Aluminum Processors in 🇺🇸 USA.

The process of converting plastic-insulated copper wire into Copper Millberry Scrap involves several stages that ensure the efficient extraction and refinement of copper from insulated wires. The primary goal is to recover high-purity copper that can be reused in various applications. Here’s a detailed description of the process:

The first step involves the collection of plastic-insulated copper wires. These wires can come from

various sources, including construction sites, electrical equipment, and discarded household appliances.

Once collected, the wires are sorted based on their type and copper content.

Manual sorting or automated systems using sensors can be employed to separate wires that contain significant amounts of copper from those with lesser amounts or different materials.

Stripping machines or hand tools are used to remove the plastic insulation from the copper wire. This step can vary in complexity depending on the thickness and type of insulation. Mechanical strippers are often used for high-volume processing, while manual stripping may be suitable for smaller operations.

Throughout the process, efforts are made to minimize environmental impact. This includes proper disposal or recycling of the plastic insulation and the use of energy-efficient machinery. Additionally, some facilities may employ closed-loop systems to recycle water and reduce waste.

Converting plastic-insulated copper wire into copper millberry scrap is a multi-stage process that involves collection, sorting, stripping, shredding, separation, refinement, and quality control. Each stage is critical in ensuring that the end product is high-purity copper, suitable for reuse in various industrial applications. This process not only recovers valuable copper but also contributes to environmental sustainability by recycling materials that would otherwise end up in landfills.

Granulation is a common method, especially in large-scale recycling operations. It involves shredding the insulated copper wire into small pieces, which are then separated into copper and plastic components. This method is frequently used because:

Granulation is particularly favored for processing mixed wire types and sizes, where manual stripping would be impractical or inefficient. It is also preferred when dealing with wires that have tough or multiple layers of insulation.

Stripping the insulation from the wire is another method used in the production of Copper Millberry Scrap. This method is typically employed in scenarios such as:

Cleaning: The granulated copper is washed to remove any remaining impurities or dust. This step ensures the copper meets the high standards required for Millberry scrap.

Samples of the copper are taken and analysed to ensure they meet the specifications for Millberry scrap. This includes checking the purity and the absence of contaminants.

Packaging:The refined copper is packaged in bales or drums, ready for transport. Proper packaging is crucial to protect the copper from damage or contamination during transit.

Distribution: The packaged copper Millberry scrap is then distributed to buyers, typically smelters or manufacturers who will use the high-purity copper in the production of new copper products.

The production of large copper cathodes shipped in container loads involves several stages, from mining the raw ore to refining and finally shipping the finished product. Here’s a detailed description of the process:

Mining: Copper ore is extracted from open-pit or underground mines. The ore typically contains less than 1% copper along with other minerals and impurities.

Crushing and Grinding: The mined ore is transported to a processing plant where it is crushed into smaller pieces. It is then ground into a fine powder to liberate the copper minerals from the surrounding rock.

Flotation: The ground ore is mixed with water and chemicals to create a slurry. This slurry undergoes a process called froth flotation, where air bubbles are introduced. The copper minerals attach to the bubbles and rise to the surface, forming a froth that can be skimmed off. This froth, now called concentrate, contains about 20-30% copper.

Roasting: The concentrate is heated in a furnace to remove some of the sulfur and moisture, converting it into a material called calcine.

Smelting: The calcine is then smelted in a furnace, where it is heated to high temperatures. This causes the copper to separate from the iron and other impurities, forming a molten mixture called matte, which contains about 60-70% copper.

Converting: The matte is transferred to a converter furnace, where it is further heated and blown with air or oxygen. This process removes more impurities, producing blister copper, which is about 98-99% pure.

Fire Refining: The blister copper is further refined in a fire refining furnace to remove remaining impurities, resulting in anode copper, which is about 99.5% pure.

Electrolytic Refining: The anode copper is cast into large slabs, called anodes, and placed into an electrolytic cell. The cell contains an acidic copper sulfate solution. An electric current is passed through the cell, causing the copper to dissolve from the anode and deposit onto a cathode, which is a thin sheet of pure copper. This process continues until thecathode reaches a purity of 99.99% copper.

Stripping and Washing: The copper cathodes are periodically removed from the electrolytic cells. They are stripped from the stainless steel or titanium starter sheets, washed to remove any residual electrolyte, and inspected for quality.

Bundling: The cleaned copper cathodes, which are typically in the form of large sheets, are bundled together. Each cathode sheet usually weighs around 100-200 kilograms.

Packaging: The cathodes are stacked and secured on pallets or bundled together using metal straps. Each bundle is tagged with information for traceability, such as batch numbers and quality

Loading: The bundled copper cathodes are then loaded into shipping containers. Standard containers can hold approximately 20-25 metric tons of copper cathodes, depending on

the size and weight of the bundles.

Shipping: The containers are transported to ports for international shipping. They are loaded onto container ships and sent to their destinations, typically to manufacturers who will use the copper in various industrial applications.

Waste Management: Throughout the process, waste materials such as tailings from concentration, slag from smelting, and electrolyte from refining are managed responsibly. Many facilities have measures in place to recycle or safely dispose of these by-products.

Energy Efficiency: The production process is energy-intensive. Efforts are made to use energy efficient technologies and practices to reduce the carbon footprint of copper production.

At Global Metal Scrappers, we specialize in buying and selling premium quality metal scrap to meet the diverse needs of our clients. Among the various types of metal scraps, copper stands out due to its wide range of applications and high recyclability. Today, we’ll focus on two of the most sought-after copper scraps: Copper Millberry and Copper Cathode Scrap.

Welcome to Global Metal Scrappers, your premier destination for selling high-quality metal scrap. With a strong commitment to excellence and sustainability, we have established ourselves as a trusted name in the metal recycling industry. Our extensive network, rigorous quality control, and exceptional customer service set us apart from the competition.

Call Us Now

Get Answers

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec rhoncus dolor at libero ultricies ullamcorper vel ut dui. Maecenas sollicitudin risus non faucibus blandit. Nulla facilisi.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec rhoncus dolor at libero ultricies ullamcorper vel ut dui. Maecenas sollicitudin risus non faucibus blandit. Nulla facilisi.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec rhoncus dolor at libero ultricies ullamcorper vel ut dui. Maecenas sollicitudin risus non faucibus blandit. Nulla facilisi.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec rhoncus dolor at libero ultricies ullamcorper vel ut dui. Maecenas sollicitudin risus non faucibus blandit. Nulla facilisi.

Copper Millberry is known for its high purity, making it a favorite in the recycling industry. This type of scrap typically consists of unalloyed, uncoated, and untinned wire with a diameter of 1.6 mm or more. The key characteristics of Copper Millberry include:

Copper Cathode Scrap is another high-grade form of copper scrap, often sourced from the smelting and refining of copper ores. Copper cathodes are flat, rectangular plates with a high purity level, typically around 99.99%. The main features of Copper Cathode Scrap include:

At Global Metal Scrappers, we understand the importance of high-quality materials in your production processes. Our copper scraps, including Copper Millberry and Copper Cathode Scrap, are sourced from reputable suppliers and undergo rigorous quality checks to ensure they meet the highest industry standards. Whether you are looking to buy or sell, we offer competitive prices and excellent service.

We guarantee the purity and consistency of our copper scraps, ensuring that you receive only the best materials for your needs.

By choosing our copper scrap, you contribute to environmental sustainability through the recycling and reuse of valuable resources.

Our commitment to customer satisfaction means that we provide reliable, timely deliveries and exceptional customer service.

For buyers, we provide high-quality copper scrap that meets industry standards. Our rigorous quality control ensures you receive the best materials for your production needs.

Whether you are looking to buy Copper Millberry or Copper Cathode Scrap, Global Metal Scrappers is your trusted partner. Our dedication to quality and sustainability ensures that you receive the best copper scrap for your industrial applications. Contact us today to learn more about our products and how we can meet your specific needs.

Testimonials

Faehan is very honest and hard-working. He ia always working with us to make sure we are completely happy with his products. The price is very fair. I have never met a company that goes out of its way to make sure you are taken care of.

Introducing Farhan Bin Samad. our trusted importer for 3.5 Years. He provided excellent adult urns and handled manufacturing and importing processes seamlessly. He's Resourceful and trustworthy, as demonstrated by finding an India Bookbinder and making timely adjustments. I highly recommend his importing company.

From our team here at Buhi Imports Inc. We all agree that our products have been of great quality. The items are heavy enough to prevent any easy denting. We appreciate you working with our designs and executing them as planned. The finishes have been as good in person as in the photos. We look forward to more orders in the future.

Business Analytics

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Founder

Make An Call

The production of large copper cathodes involves a complex series of steps from mining and processing ore to refining and shipping the final product. Each stage is crucial in ensuring the production of high-purity copper that meets industry standards. The process is designed to be efficient and environmentally responsible, providing a vital material for various industrial applications worldwide